© 2019 Burt Forest Products

Particleboard is made from small wood particles pressed together with glue under extreme heat and pressure to make a solid panel. MDF and hardboard are made the same way except the wood particles are further refined into even smaller particles to provide a smooth edge to the panel.

Composite wood panels are often surfaced with a decorative treatment. There are a number of surfacing options available that can be used to create the wonderful array of looks and styles that consumers want and expect.

Composite wood panels are often surfaced with a decorative treatment. There are a number of surfacing options available that can be used to create the wonderful array of looks and styles that consumers want and expect.

COMPOSITE PANELS

Particleboard is a composite panel product consisting of cellulosic particles of various sizes that are bonded together with a synthetic resin or binder under heat and pressure. Particle geometry, resin levels, board density and manufacturing processes may be modified to produce products suitable for specific end uses. At the time of manufacture, additives can be incorporated to impart specific performance enhancements including greater dimensional stability, increased fire retardancy and moisture resistance.

The term "composite wood products" refers to a family of engineered wood panels that includes particleboard, MDF (medium density fiberboard), and hardboard.

Medium Density Fiberboard (MDF) is widely used in the manufacturing of furniture, kitchen cabinets, door parts, mouldings, millwork and laminate flooring.

The surface of MDF is flat, smooth, uniform, dense and free of knots and grain patterns. The homogeneous density profile of MDF allows intricate and precise machining and finishing techniques for superior finished products. Trim waste is significantly reduced when using MDF compared to other substrates. Stability and strength are important assets of MDF, which can be machined into complex patterns that require precise tolerances.

The surface of MDF is flat, smooth, uniform, dense and free of knots and grain patterns. The homogeneous density profile of MDF allows intricate and precise machining and finishing techniques for superior finished products. Trim waste is significantly reduced when using MDF compared to other substrates. Stability and strength are important assets of MDF, which can be machined into complex patterns that require precise tolerances.

Medium Density

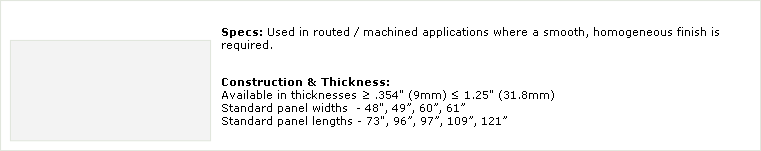

Weyerhaeuser Super-Refined MDF2 ® is an engineered wood panel prized by woodworkers for its exceptional qualities, including smooth, unblemished surface and homogeneous core. Our products are made from high-quality inland species of western softwoods known for their low abrasive content and light color, providing for unsurpassed ease of routing and finishing.